Usual Concerns Addressed by Commercial Refrigerator Repair Specialists in Toronto

Usual Concerns Addressed by Commercial Refrigerator Repair Specialists in Toronto

Blog Article

The Ultimate Overview to Commercial Refrigeration Repair: Necessary Steps and Usual Issues Explained

Typical Industrial Refrigeration Issues

When operating industrial refrigeration units, companies might run into several common issues that can affect the efficiency and performance of the tools. One prevalent problem is inappropriate temperature regulation. Varying temperatures within the refrigeration device can result in food putridity, boosted power intake, and jeopardized quality and safety and security standards. This problem usually originates from a faulty thermostat, improper door seals, or insufficient insulation.

Another usual issue is refrigerant leaks. Leakages can result from damage, inadequate installment, or manufacturing defects. If left unaddressed., low cooling agent degrees not just prevent the device's cooling capacity but can likewise lead to compressor failure.

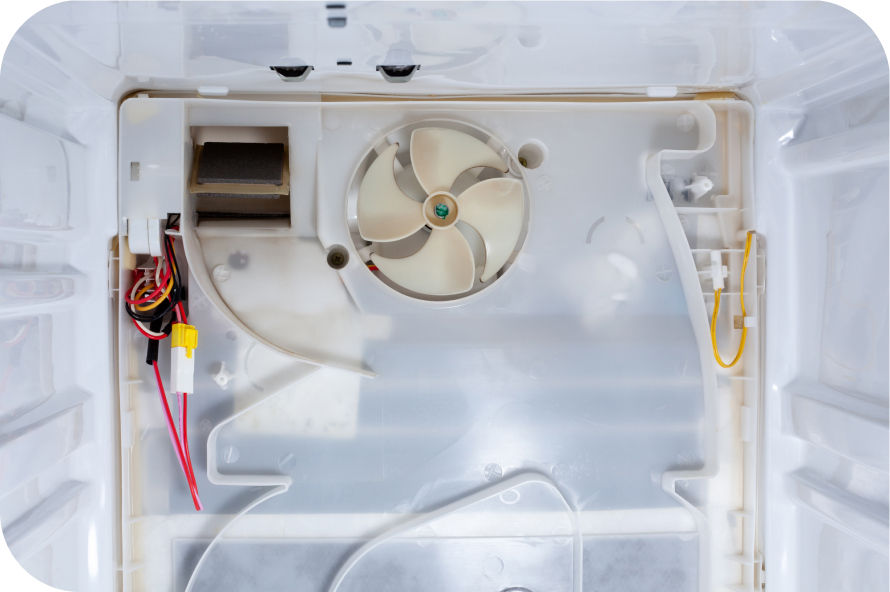

Furthermore, ice buildup on evaporator coils is a frequent worry. Ice buildup restricts air movement, causing the unit to function more challenging and take in more power. Normal cleansing and upkeep of the coils can help prevent this problem.

Crucial Devices for Repairing Refrigeration Devices

Using the proper devices is critical for properly fixing business refrigeration units to ensure optimum efficiency and longevity. Amongst the basic tools required are manifold determines for examining refrigerant pressures, refrigeration wrenches for tightening or loosening fittings, a multimeter for screening electric elements, and leak detection tools such as electronic leakage detectors or ultraviolet color packages.

In the realm of specialized tools, tube cutters and flaring tools are necessary for dealing with copper tubes, while a recuperation device is essential for securely eliminating refrigerants. In addition, a temperature level weapon can be beneficial for swiftly determining temperature differentials within the device. Buying top quality tools not just enhances performance throughout repairs yet also adds to the precision and dependability of the upkeep job accomplished on commercial refrigeration systems.

Step-by-Step Troubleshooting Overview

The next action is to examine the temperature controls and setups to guarantee they are working correctly. This includes checking the thermostat, defrost timer, and various other control devices to validate that they are managing home the temperature level as planned. If any kind of discrepancies are located, modifications or substitutes might be necessary. commercial refrigerator repair.

Consequently, the professional needs to check out the condenser and evaporator coils for dirt or particles accumulation, which can restrain appropriate cooling. Cleansing these parts can commonly resolve problems with temperature level guideline and effectiveness.

Preventative Upkeep Techniques

Implementing routine preventative upkeep steps is important for making certain the durability and ideal efficiency of commercial refrigeration systems. By sticking to a proactive upkeep routine, services can lessen the threat of costly breakdowns, protect against downtime, and prolong the lifespan of click to find out more their refrigeration devices.

One essential preventative upkeep method is routine cleaning of condenser coils. With time, these coils can build up dirt, particles, and dust, which can impede warmth transfer and decrease the system's performance. By cleaning the coils occasionally, organizations can make sure that the refrigeration system operates at peak efficiency.

Additionally, examining and replacing worn gaskets on doors is an additional critical maintenance task. Harmed gaskets can lead to air leaks, creating the refrigeration system to work more challenging to keep the desired temperature level. By changing damaged gaskets promptly, companies can boost power efficiency and prolong the life of the devices.

Including these preventative maintenance techniques into a thorough maintenance plan can help companies maximize the performance and integrity of their industrial refrigeration systems.

Professional Fixing Vs. DIY: Pros and Disadvantages

Involving a specialist repair solution for industrial refrigeration systems supplies distinctive benefits over attempting Do it yourself repair services. Industrial refrigeration systems are complicated systems that call for specialized understanding and abilities to detect and repair effectively.

Trying to repair an industrial refrigeration system yourself can lead to further damage if not done correctly, potentially resulting in even more pricey repair services down the line. While Do it yourself repair services may seem economical at first, the long-term advantages of professional fixing solutions outweigh the unpredictabilities and risks connected with attempting repair services on your own.

Conclusion

Finally, understanding usual industrial refrigeration concerns, having the check it out vital devices for repair work, following a detailed troubleshooting guide, and implementing preventative maintenance techniques are vital parts of maintaining and fixing business refrigeration systems. While professional repair work solutions may offer experience and performance, do it yourself repair services can also be a cost-efficient alternative for those with the essential abilities and understanding. Ultimately, routine maintenance and punctual repair services are essential for ensuring the appropriate functioning of commercial refrigeration units.

Recognizing the important steps for commercial refrigeration repair and being able to identify common problems are critical abilities for any kind of company owner or maintenance workers. In this extensive overview, we will certainly explore the fundamental steps and common problems in commercial refrigeration repair, equipping you with the understanding required to deal with these obstacles properly.

Involving a professional repair solution for business refrigeration systems supplies distinct benefits over attempting Do it yourself repair services. Attempting to repair a business refrigeration system yourself can lead to additional damage if not done properly, potentially resulting in more costly fixings down the line.In conclusion, comprehending common commercial refrigeration concerns, having the necessary devices for repair, adhering to a detailed troubleshooting overview, and carrying out preventative maintenance methods are essential elements of keeping and fixing business refrigeration devices.

Report this page